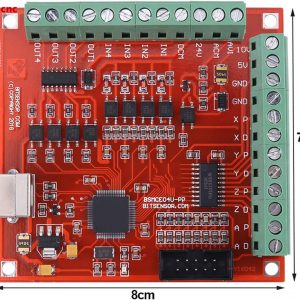

انواع درایور و موتور

کنترلر CNC چهار محور با پردازنده DSP برند RichAuto مدل A18

34,450,000 تومان

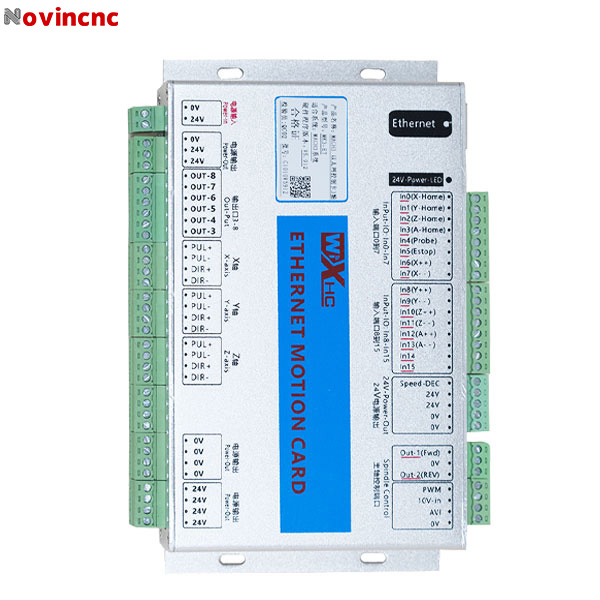

کنترلر CNC سه محور MACH3 دارای ارتباط Ethernet مدل MK3 ET

12,620,000 تومان

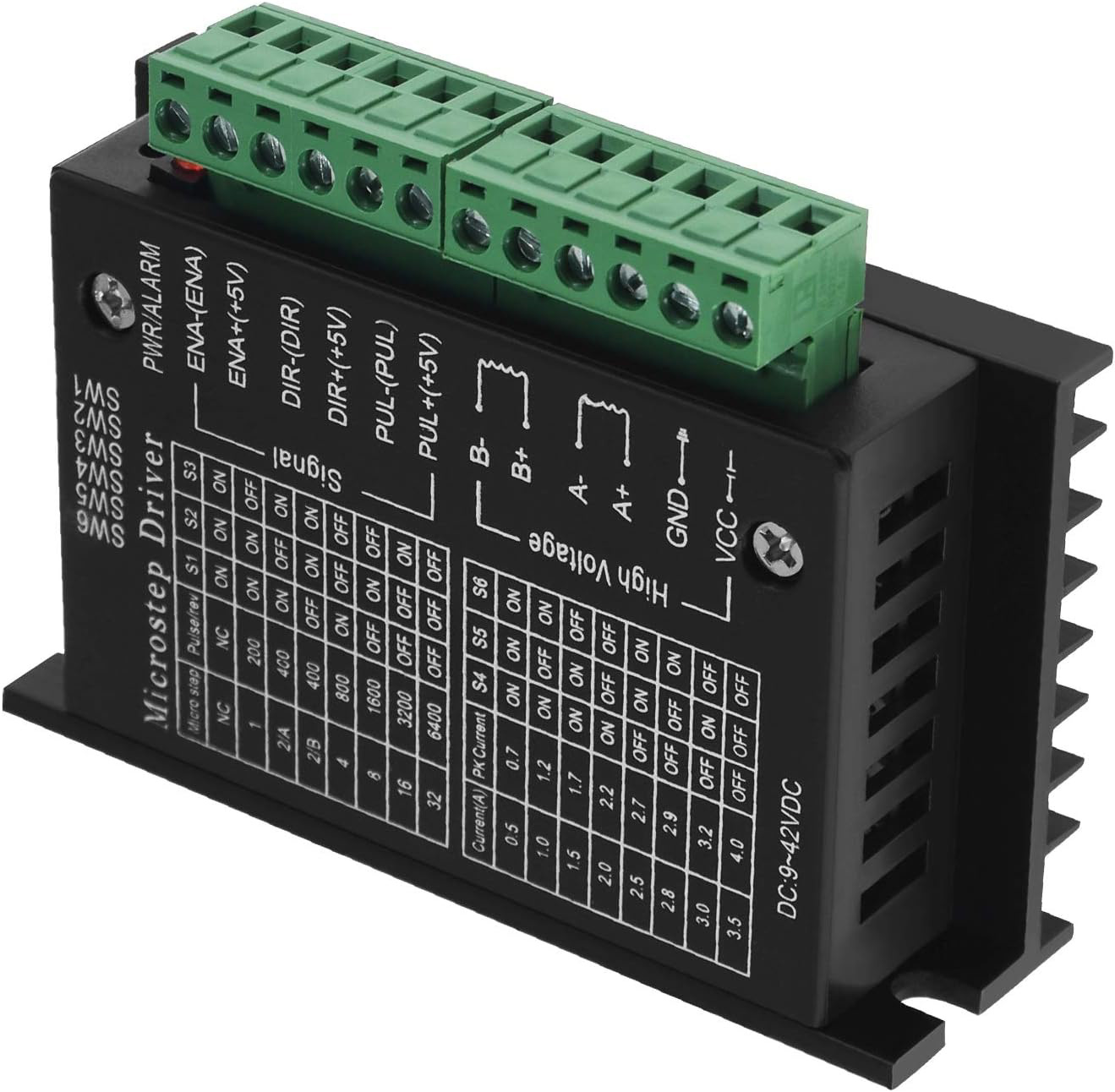

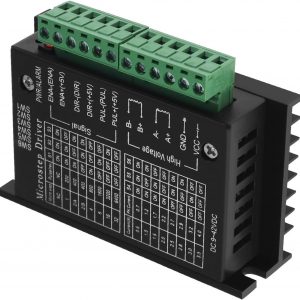

قیمت و خرید درایور tb6600

امتیاز 5.00 از 5

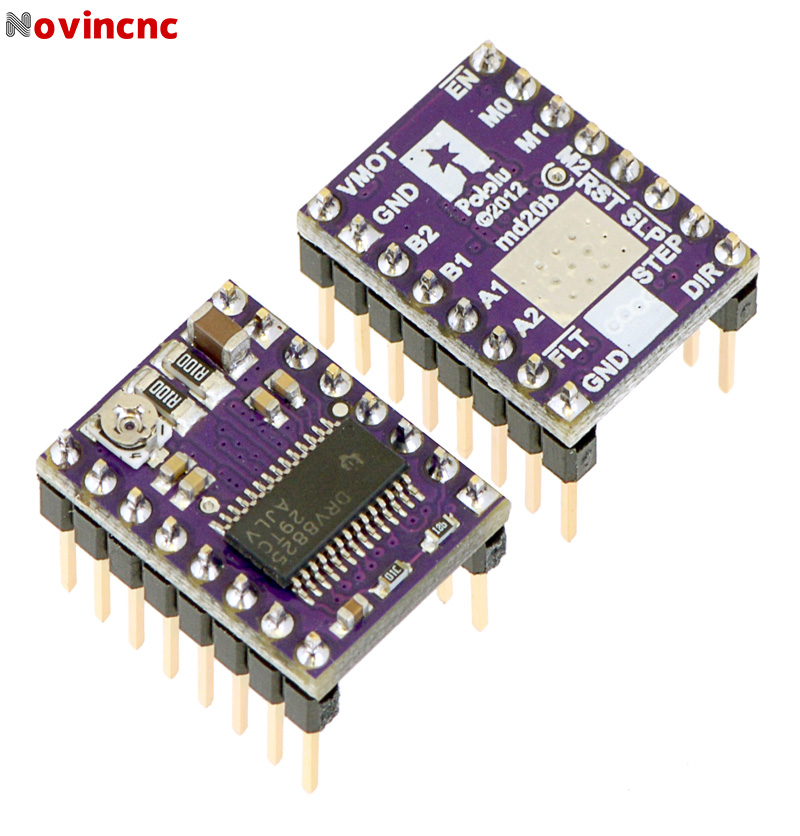

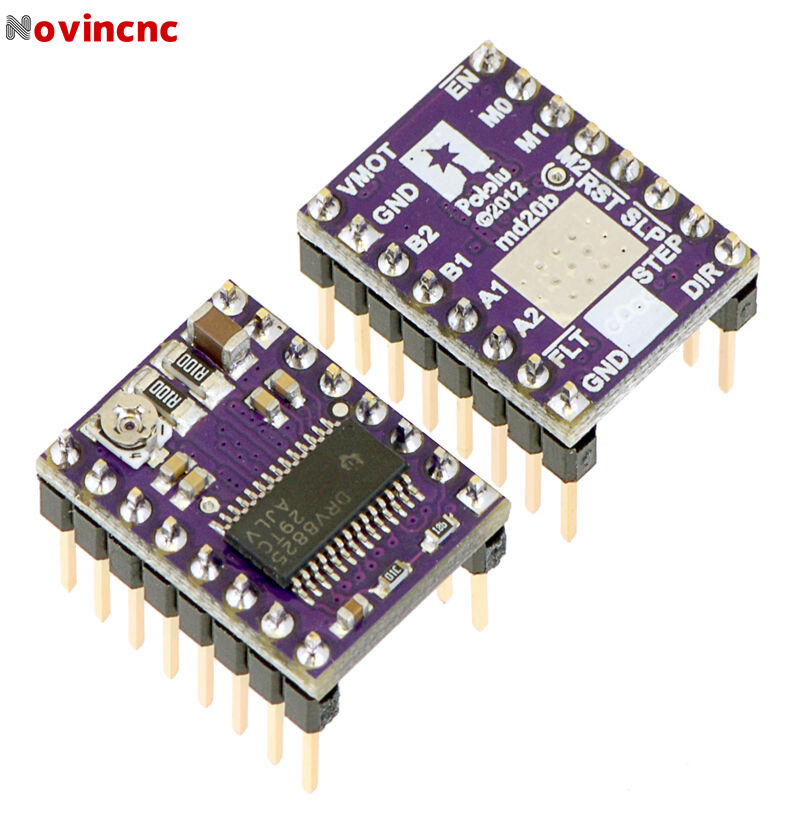

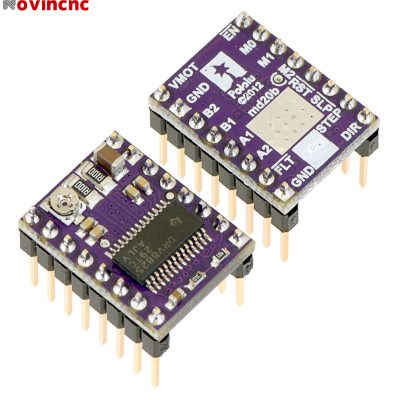

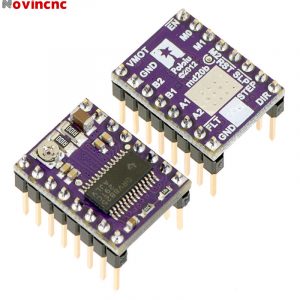

قیمت و خرید ماژول درایور drv8825

امتیاز 5.00 از 5

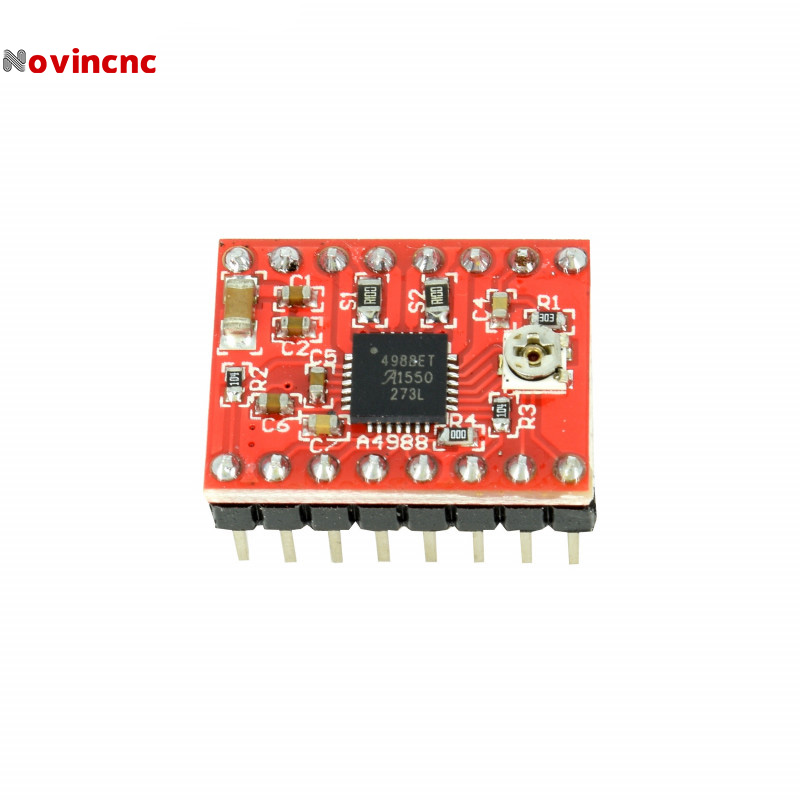

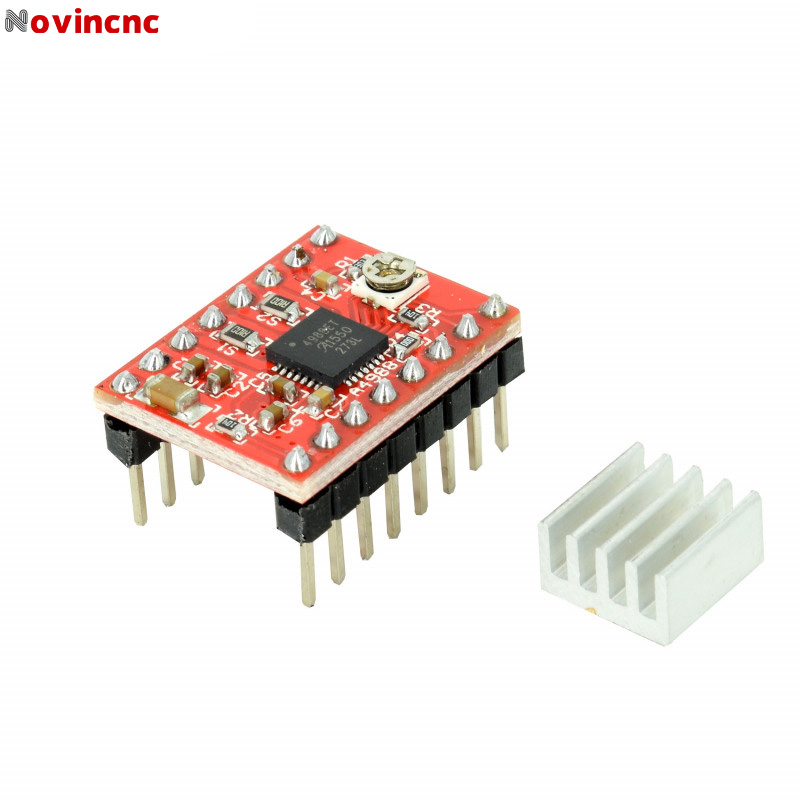

قیمت و خرید ماژول درایور a4988

امتیاز 5.00 از 5

آفروز | پیشنهادات وودمارت

مجله زیبایی

01

بهمن

3 نکته نگهداری از ریل و واگن

3 نکته نگهداری از ریل و واگن کدامند با توضیح ؟

3 نکته نگهداری از ریل و واگن کدامند ؟نگهداری از ریل ...

01

بهمن

ریل و واگن چیست ؟

ریل واگن چیست و توضیحات تکمیلی در مورد ریل و واگن :

ریل و واگن چیست ؟ریل و واگن اجزای اصلی سیستم ر...

01

بهمن

کوپلینگ چیست ؟

کوپلینگ چیست ؟ و موارد کاربرد کوپلینگ :

کوپلینگ چیست ؟ کوپلینگ به طور کلی به وسیلهای اطلاق میشود ...

01

بهمن

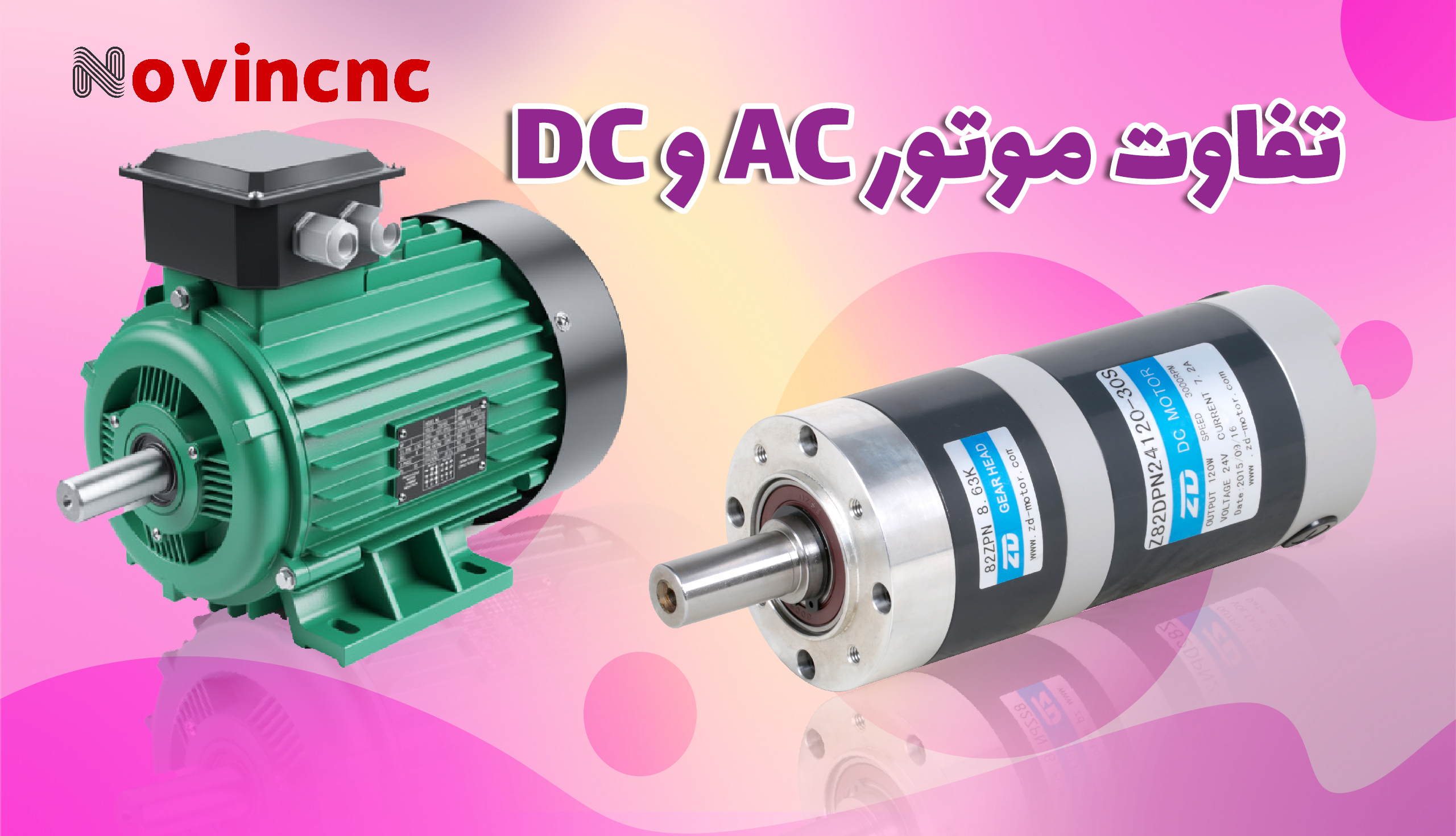

تفاوت موتور ac و dc چیست ؟

تفاوت موتور AC و DC چیست ؟

تفاوت موتور ac و dc چیست ؟ موتورهای AC (جریان متناوب) و DC (جریان مستقیم...

01

بهمن

بال اسکرو چیست ؟

بال اسکرو چیست و توضیحاتی در مورد بال اسکرو :

بال اسکرو چیست و توضیحاتی در مورد بال اسکرو : بال اس...

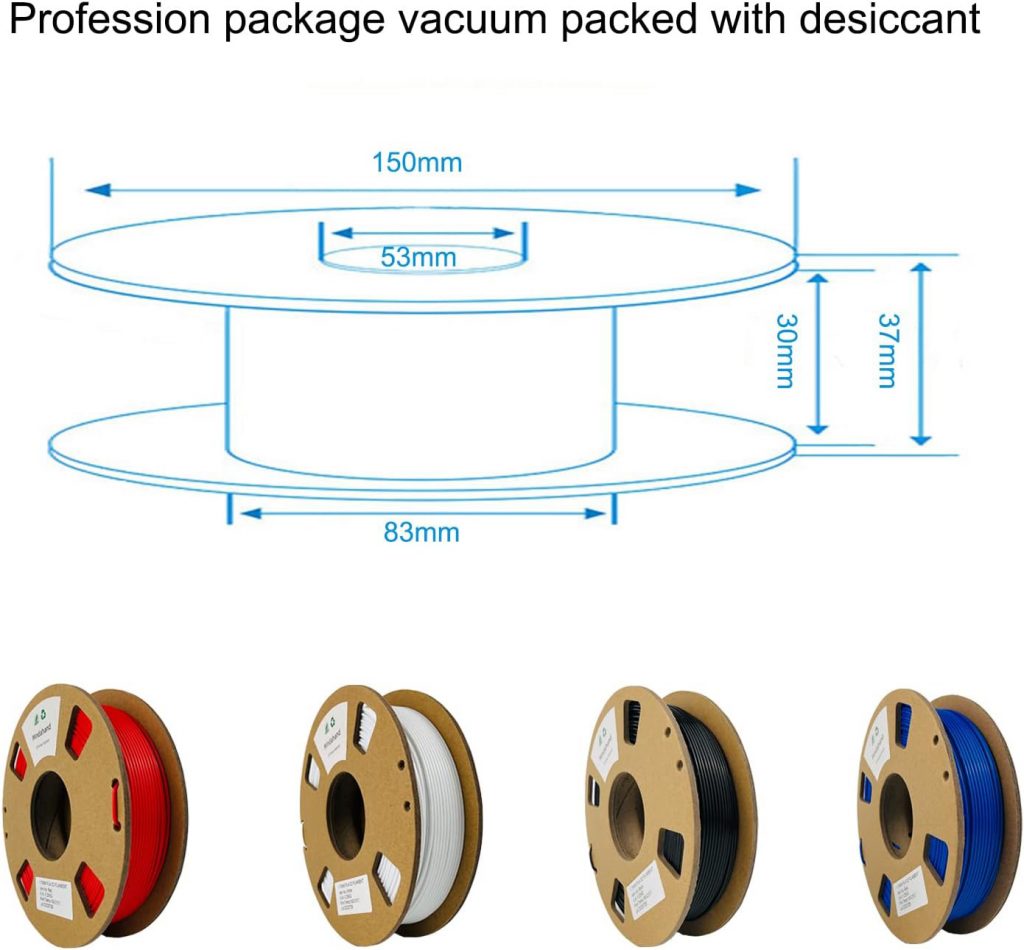

فیلامنت پرینتر سه بعدی

فیلامنت PLA سفید میندا قطر 1.75

880,000 تومان

فیلامنت PLA زرد میندا قطر 1.75

880,000 تومان

فیلامنت PLA نارنجی میندا قطر 1.75

880,000 تومان

فیلامنت PLA سیاه میندا قطر 1.75

880,000 تومان

فیلامنت PLA خاکستری میندا قطر 1.75

880,000 تومان