انواع درایور و موتور

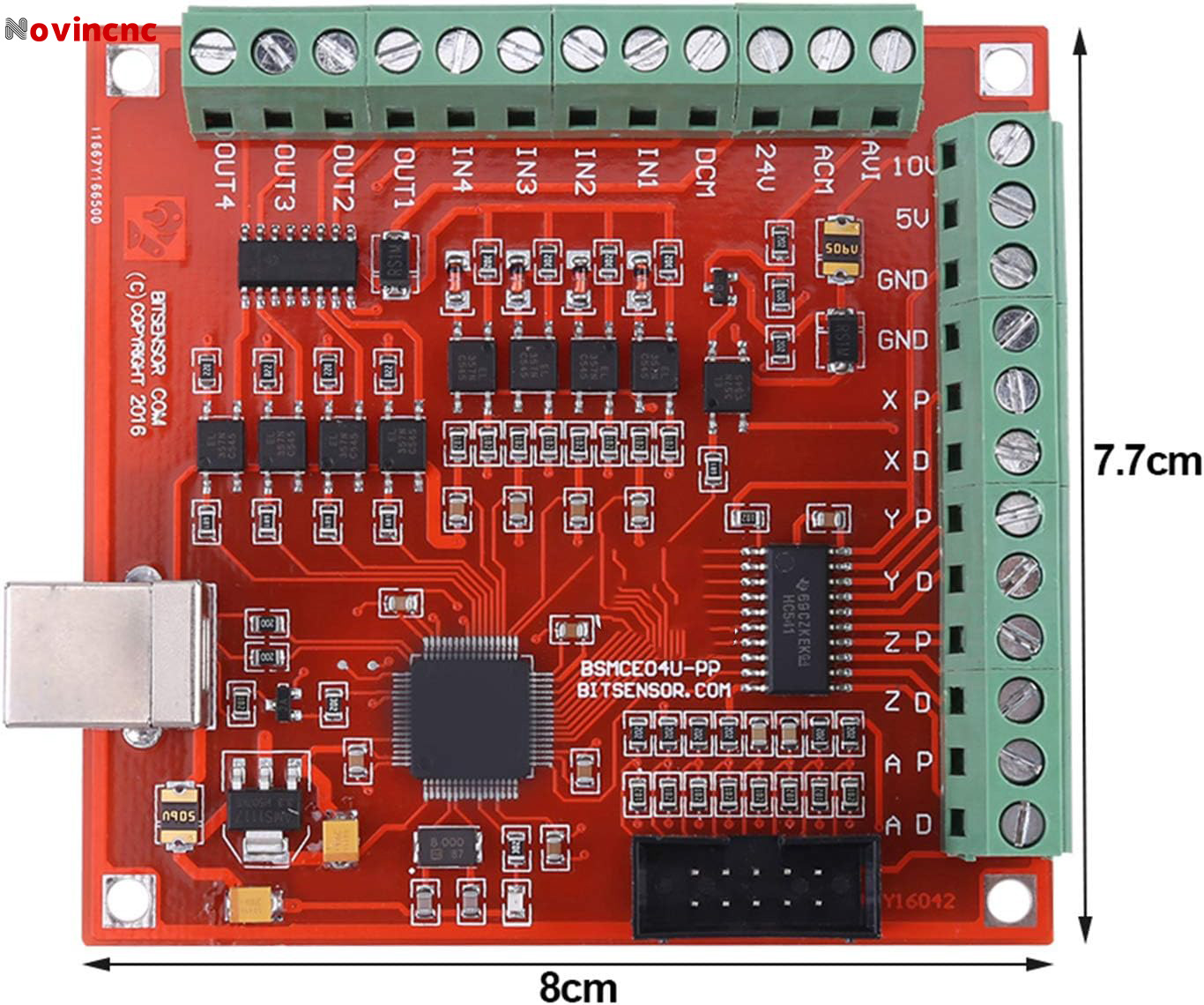

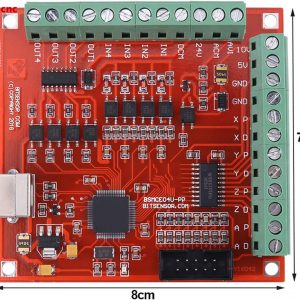

برد کنترلر CNC چهار محور USB Mach3 با خروجی ۱۰۰KHz

امتیاز 5.00 از 5

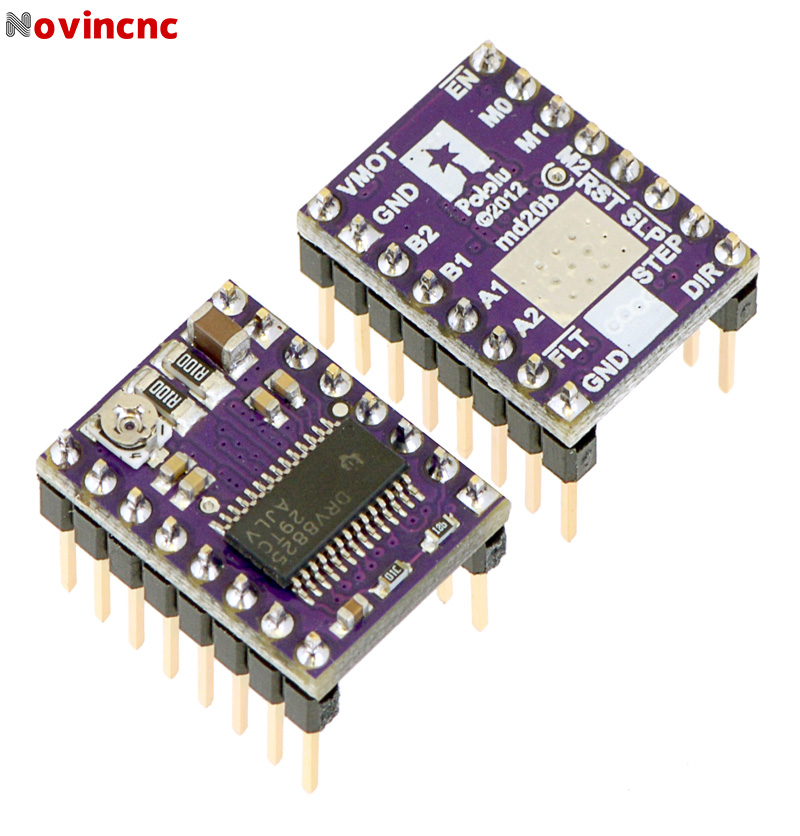

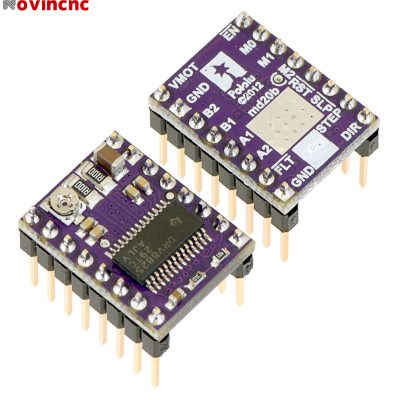

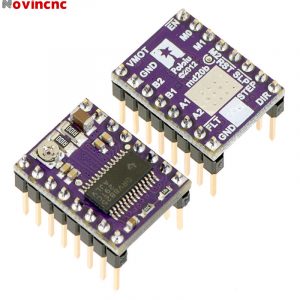

قیمت و خرید ماژول درایور drv8825

امتیاز 5.00 از 5

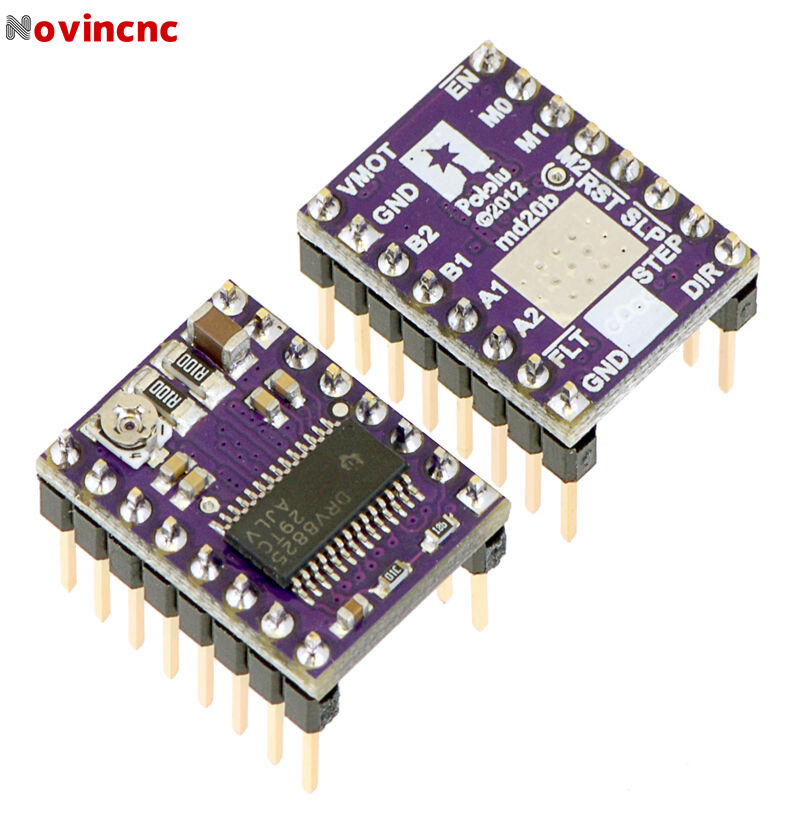

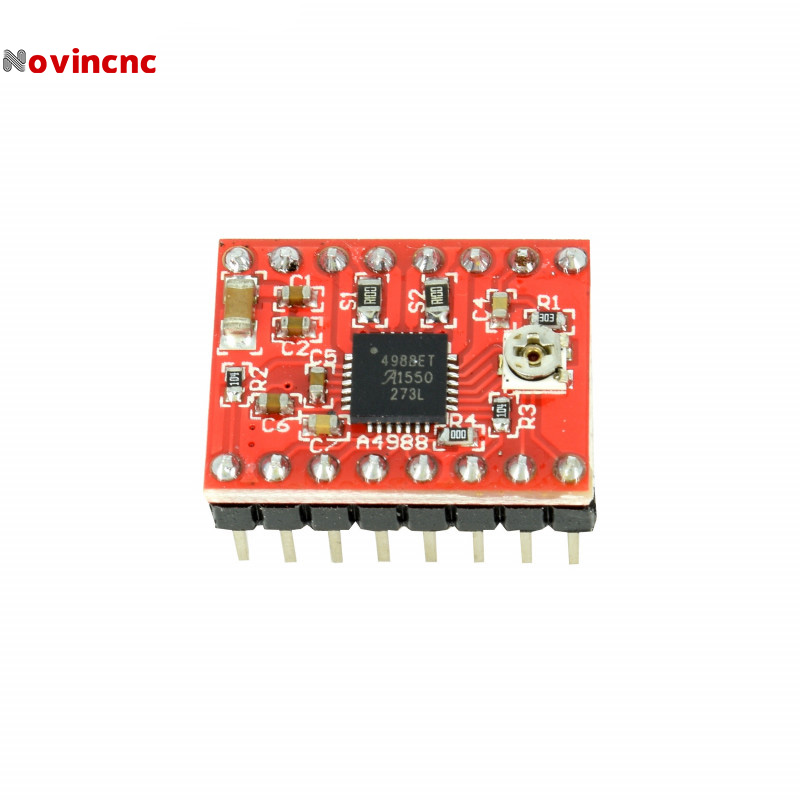

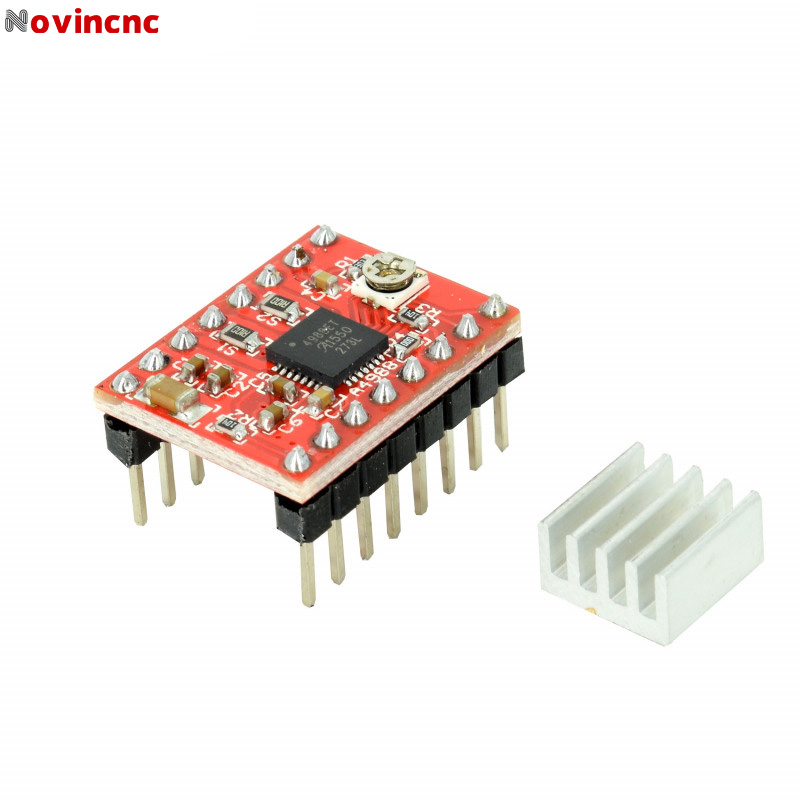

قیمت و خرید ماژول درایور a4988

امتیاز 5.00 از 5

برد کنترلر CNC چهار محور USB Mach3 با خروجی ۱۰۰KHz

امتیاز 5.00 از 5

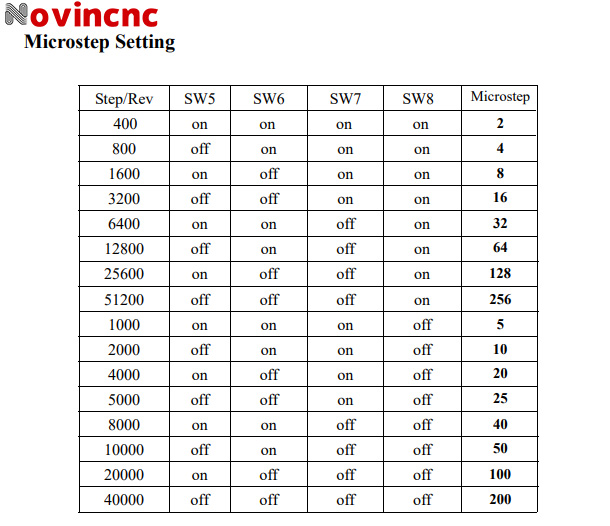

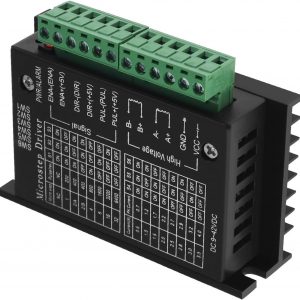

قیمت و خرید درایور tb6600

امتیاز 5.00 از 5

قیمت و خرید ماژول درایور drv8825

امتیاز 5.00 از 5

قیمت و خرید ماژول درایور a4988

امتیاز 5.00 از 5

کیت مینی سی ان سی رو میزی (mini cnc) مدل CNC3018 pro

امتیاز 5.00 از 5

آفروز | پیشنهادات وودمارت

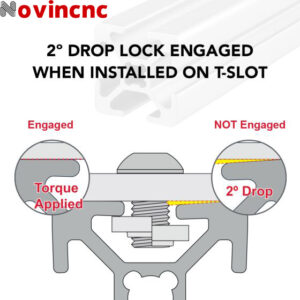

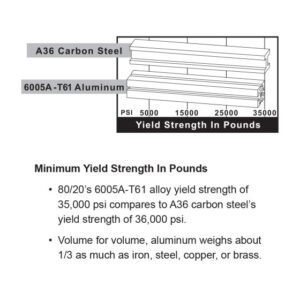

پروفیل آلومینیوم شیاردارصنعتی 45 در 90 سبک

17,340 تومان برای هر واحدپروفیل آلومینیوم شیاردار صنعتی 22.5 در 180

28,600 تومان برای هر واحدپروفیل آلومینیوم شیاردار صنعتی 30 در 30 سنگین

4,230 تومان برای هر واحدبرد کنترلر CNC چهار محور USB Mach3 با خروجی ۱۰۰KHz

امتیاز 5.00 از 5

قیمت و خرید درایور tb6600

امتیاز 5.00 از 5

قیمت و خرید ماژول درایور drv8825

امتیاز 5.00 از 5

قیمت و خرید ماژول درایور a4988

امتیاز 5.00 از 5

کیت مینی سی ان سی رو میزی (mini cnc) مدل CNC3018 pro

امتیاز 5.00 از 5

مجله زیبایی

آموزش نرم افزار کندل ( تصویری ) و دانلود رایگان

آموزش نرم افزار کندل برای سی ان سی 3018 (راهنمای جامع)

در این اموزش قصد داریم آموزش نرم افزار کندل...

3 نکته نگهداری از ریل و واگن

3 نکته نگهداری از ریل و واگن کدامند با توضیح ؟

3 نکته نگهداری از ریل و واگن کدامند ؟نگهداری از ریل ...

ریل و واگن چیست ؟

ریل واگن چیست و توضیحات تکمیلی در مورد ریل و واگن :

ریل و واگن چیست ؟ریل و واگن اجزای اصلی سیستم ر...

کوپلینگ چیست ؟

کوپلینگ چیست ؟ و موارد کاربرد کوپلینگ :

کوپلینگ چیست ؟ کوپلینگ به طور کلی به وسیلهای اطلاق میشود ...

تفاوت موتور ac و dc چیست ؟

تفاوت موتور AC و DC چیست ؟

تفاوت موتور ac و dc چیست ؟ موتورهای AC (جریان متناوب) و DC (جریان مستقیم...

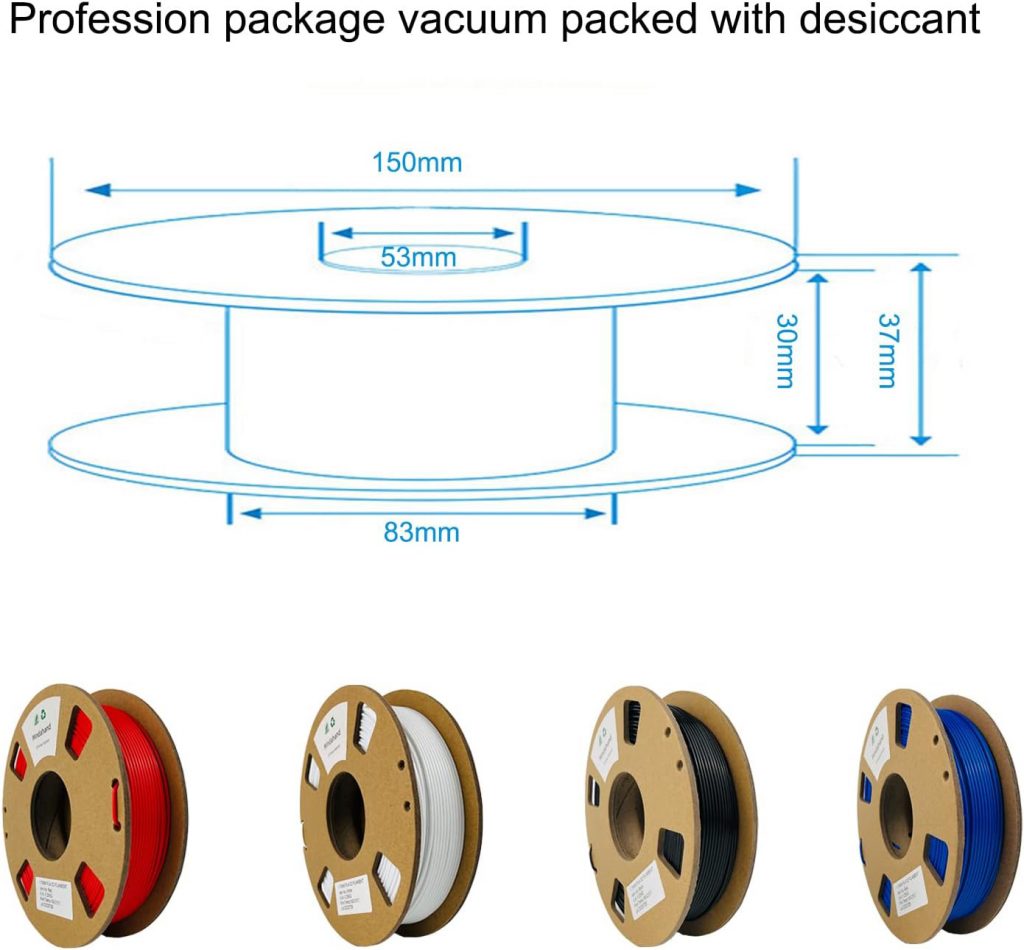

فیلامنت پرینتر سه بعدی

فیلامنت PLA سفید میندا قطر 1.75

1,250,000 تومان

فیلامنت PLA زرد میندا قطر 1.75

1,250,000 تومان

فیلامنت PLA نارنجی میندا قطر 1.75

1,250,000 تومان

فیلامنت PLA سیاه میندا قطر 1.75

1,250,000 تومان

فیلامنت PLA خاکستری میندا قطر 1.75

1,250,000 تومان